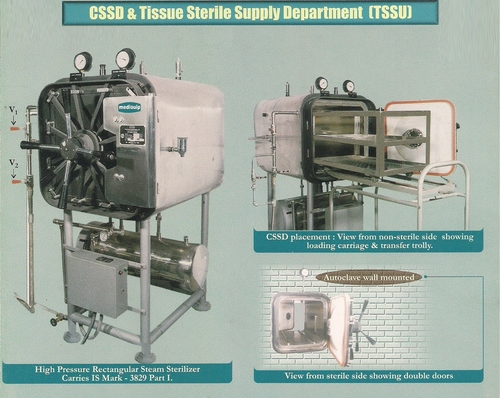

High Pressure Rectangular Steam Sterilizer

SALIENT FEATURES

- Best Suited for parental solutions, injectable, mattresses and hospital dressings

- Loading carriage and trolley as standard accessories for easy transfer of loads.

- Multiport value to control different phases of sterilizing cycle up to size 2’x3’x5′

- Individual valves for size above 2’x3’x5

- Operating pressure up to 1.76 Kg./cm2

- All SS joint are argon are welded

- Outgoing pipes from the sterilizer made of SS.

- Choice of single/double doors and recessed models.

- Two Safety valves incorporated.

- Vacuum Breaker provided for entry of sterile air.

- Pressure Lock device for the door.

- Pressure switch provided to prevent accidental build up of pressure.

- Steam trap incorporated for rapid and complete elimination of air.

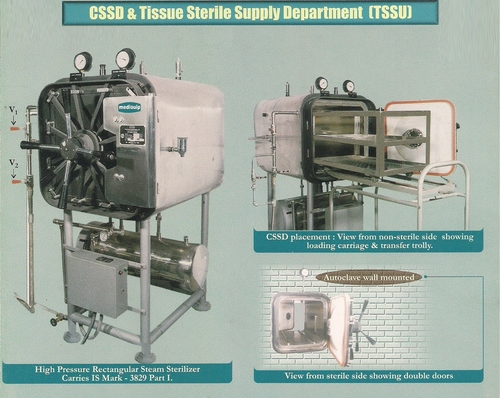

Horizontal High Pressure Sterilizer

SALIENT FEATURES

- Carries all requirements of IS Mark 3829 Part I.

- End ring hydraulically formed with joints to sustain required pressure. All Other joints argo arc welded.

- Unique multiport valve located at the top. Controls all operations manually.

- Two safety valves (dead Wt. & spring loaded)and a pressure switch provided to prevent accidental pressure build up.

- Low water level device for heater protection.

- Pressure lock device for the door.

- Works on 121 Celcius at 15 psi (1.05 kgf / cm sqr to 1.2 kgfcm sqr).

- Hydrostatically tested 2 times the working pressure.

- Vaccum system incorporated through multiport valve makes linen dry.

- Power : 9KW. 440V, 3-Phase.

- First cycle : 90 minutes.

- Possible to run at High Speed if customer wants at a later date by modifying pressure and heating devices.

- Thermograph or Electronic Chart recorder are available as optional accessories.